You’ll benefit from a CNC contract manufacturing company if you need a single part or an entire production line. Online machining companies specializing in CNC machining have the knowledge and equipment to handle projects. They provide certified technical engineers and routine maintenance tips for your CNC machine. These companies can take on multiple projects at a time.

Costs

CNC machining can be expensive, but there are ways to reduce the cost of CNC operations. For starters, optimize your design. This can help to reduce the cost per part but does not sacrifice functionality. For example, add a radius to internal vertical edges, limit the depth of a cavity, or make sure tapped holes are small. Another option is to split your complex part into smaller components. Additionally, opt for only the necessary surface finishes.

Outsourcing CNC machining is ideal for companies that do not have in-house machining capabilities. It saves time and money by freeing up the company’s employees and equipment. Plus, contract CNC machining services use the hiring company’s designs. As a result, the company’s brand is on the component. For projects involving low volume machined parts, outsourcing can be particularly cost-effective. It allows businesses to manage smaller production runs without the overhead of full-scale operations.

CNC machining costs vary by project complexity. Complex designs are more challenging to program and may involve several intricate parts. In addition, the CNC company must spend more time digitalizing the procedure.

Time

CNC machining is an efficient method for creating complex parts with various features. However, costs vary considerably. The amount you pay to a CNC machining company will determine the price of the machining process. Sometimes, you can reduce costs by reducing the number of parts you order. You can also make changes in the part’s design to reduce the cost per piece.

Contract machining may be an excellent solution for manufacturers needing to produce more complex products. Outsourcing CNC machining will allow you to avoid expensive equipment and personnel costs while keeping your production schedule on track. This method is helpful for various industries, including aerospace, medical devices, packaging, and electronics.

When contracting CNC machining, ensure the design is manufacturable. Using a design that promotes time efficiency and reduces waste is essential. In CNC machining, it is vital to minimize setup and machine time. The less time you spend setting up the machine, the more money you save.

Precision

Outsourcing CNC machining can be beneficial in several ways. For one thing, it can be less expensive than maintaining and operating a CNC machine in-house. Additionally, it allows you to focus on more mission-critical operations. By contracting the work to another company, you can free up your resources to focus on other tasks.

Contract CNC machining companies can meet tight tolerances and customer expectations. In addition, they also typically have excellent in-house quality control and certifications. Many also have design staff who can provide a more comprehensive service. For specialized materials, such as machined graphite, outsourcing to experienced CNC machining providers can ensure precise and reliable results while keeping costs down.

Another benefit of contract CNC machining is that it helps you share the production load. Since the hired company has the designs and specifications for the product, it can focus on the more critical manufacturing processes. Contract CNC machining can be used to produce one small part or a complete product line. Companies like Fast Cut CNC specialize in providing precision machining and custom fabrication services, making them an ideal partner for both small-scale and large-scale projects.

CAD design

Using CAD design software can help streamline the process of contracting CNC machining. This software helps reduce errors and time-consuming redrawing of products. It allows designers and manufacturers to interact with each other, make changes and ensure that the final product is what was intended. The software also allows manufacturers to store documents on the cloud, allowing them to share documents and easily make timely changes.

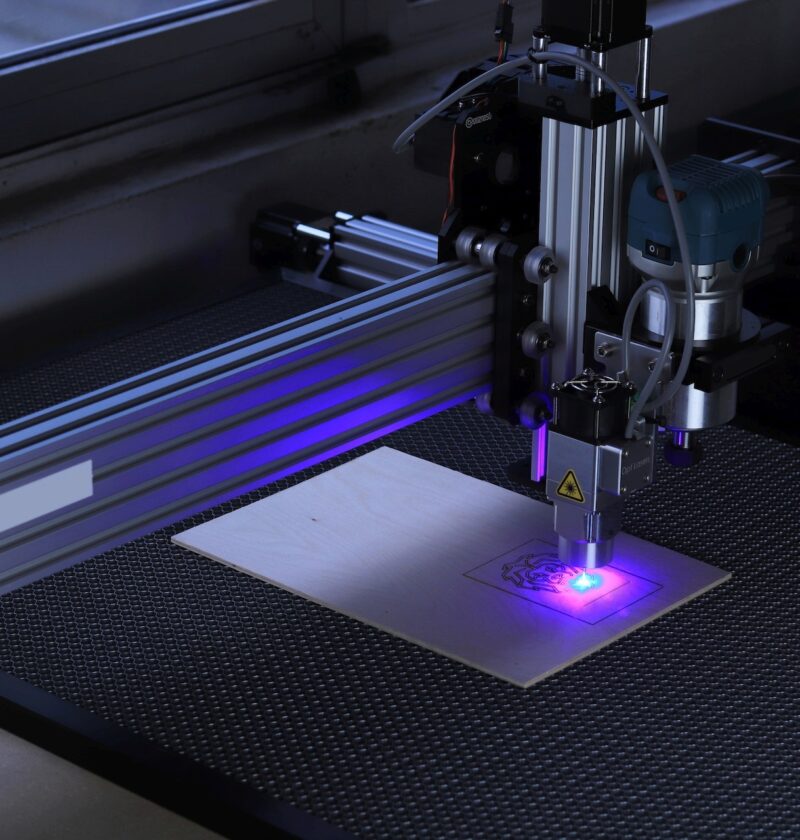

The CAD design file runs through a CNC machining software program that extracts part geometry and creates digital programming code that controls the machine and manipulates tooling. The device then produces the custom-designed part. With this software, the process becomes automated, allowing the CNC operator to complete a project faster.

CAD design software also helps manufacturers receive CAD files from clients efficiently. CAM software allows users to create a machining program without a complicated learning curve. It also allows them to see the machining process before it starts. This enables manufacturers to deliver finished products faster. In addition, CAD-CAM software helps manufacturers manage and test projects.